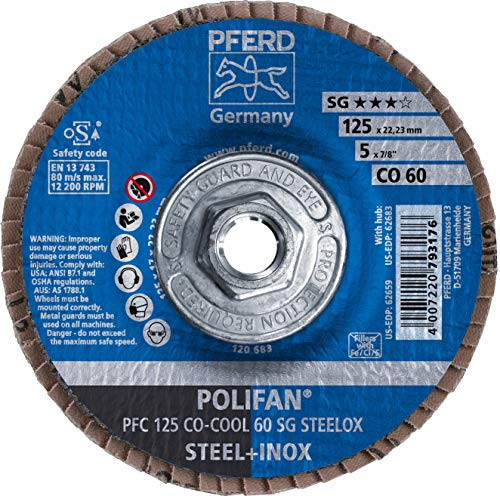

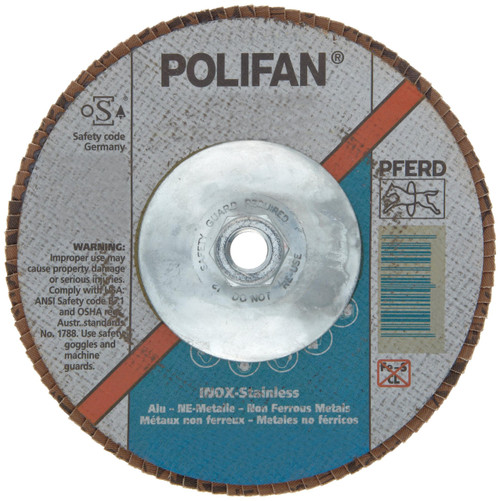

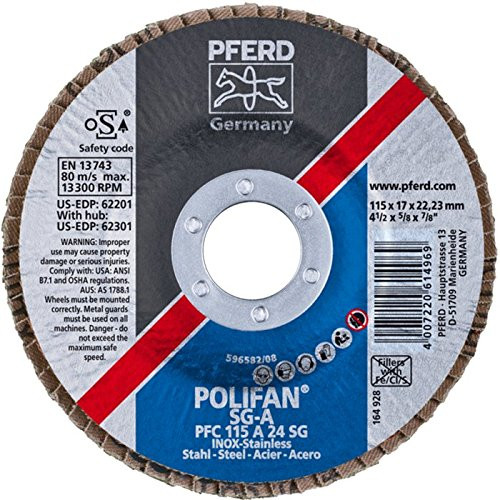

The Pferd Polifan SGP CO-Cool type 29 angled-style ceramic aluminum oxide abrasive flap disc has a phenolic resin backing for reinforcement, a threaded hole for attachment to grinding tools, and cool grinding properties for aggressive material removal and high productivity, even at low contact pressure. The ceramic aluminum oxide abrasive is a self-sharpening grit that is harder and tougher than aluminum oxide, which makes it suitable for fast material removal rates and aggressive grinding on chromium steel, chromium-nickel steel, high-alloy steel, high-carbon steel, cast iron, nickel-based alloys, titanium alloys, and nonferrous metal. It produces a high-quality, consistent finish. It is free of iron, sulphur, and chlorinated fillers. Applications include weld dressing and surface grinding. The disc shape is angled for maximum workpiece contact and is commonly used with angle grinders. Threaded hole fastening type indicates a disc with a female-threaded central hole that twists onto a threaded arbor.

Abrasive flap discs are made from overlapping pieces of coated abrasive attached to a hub. They help reduce finishing time and cost by grinding and finishing in the same step, such as when removing a weld bead and smoothing the workpiece around the weld. Flap discs are coated, meaning an adhesive is used to attach the abrasive grains to a backing of paper, plastic, or cloth. The action of a flap disc is much like that of a sanding disc: the grinding or polishing occurs on the face of the disc. They are used for a variety of applications from shaping a part to fine finishing, depending on the grit size. Low grit numbers like 40 are coarse (with fewer, larger grains) and remove excess material and shape parts. High grit numbers like 400 are fine (with more, smaller grains) and help create a smooth surface finish.

Pferd manufactures abrasives and cutting tools for grinding, finishing, and cutting. Founded in 1799 in Germany, Pferd has