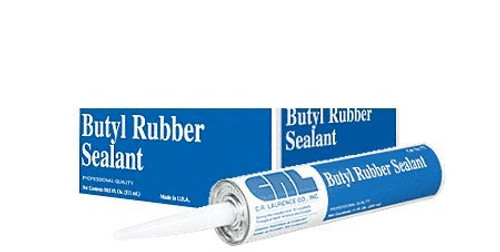

Excellent Adhesion to a Variety of Clean Surfaces Superior Exterior Weathering Properties Easy to Apply and Tool CRL 777 Butyl Rubber is a unique, butyl-based sealant specially formulated using a blend of age resistant polymers to give excellent weathering properties at various temperature extremes. CRL 777 offers excellent adhesion to most clean surfaces, and will withstand joint movement of ±10% without affecting its water-tightness. It also has a special Ultra Violet fighting agent for exceptional service life. Recommended for exterior applications, CRL 777 Butyl Rubber Sealant features excellent adhesion to wood, masonry, glass and metal surfaces. Hidden areas, such as under sill cans, thresholds, and around screw heads are excellent applications. Other areas, such as between metal building panels, wall-mounted air conditioning units, under aluminum siding and gutters are all good application for proven butyl sealants. Application temperature range is 0 to 120 degrees Fahrenheit (-18 to 49 degrees Celsius). Service temperature range is -20 to 200 degrees Fahrenheit (-29 to 93 degrees Celsius). Paint time is 24 hours. In order to help you better select the correct sealant, we have put together a Silicone and Sealant Selector Chart . Color: White Contents of Cartridge: 11 fl oz (325 ml) Technical Data : Meets Federal Specifications TT-S-001657, Type 1, TT-C00598C, TT-C-1796A, ASTM C 1311, and AAMA 808.3, USDA Certified. Comparable Sealants : Adco B-100, Adco AP-77 CRL 888 Dap Butyl-Flex OSI SBR-100 PTI757 Pecora BC-158 PSI-301 Tremco Butyl Sealant Important Note: Not recommended for use in sealing horizontal decks, patios, driveways or terrace joints where abrasion or physical abuse is encountered. Not recommended for surfaces with special protective or cosmetic coatings, and should not be applied with wet tooling techniques using solvents, water or detergent/soap solutions.

CR LAURENCE 777W CRL White 777 Butyl Rubber Sealant

MSRP:

Was:

$79.90

Now:

$39.95

(You save

)

- SKU:

- R656890

- UPC:

- Condition:

- New

- Availability:

- Free Shipping from the USA. Estimated 2-4 days delivery.

Add to Cart

The item has been added

C.R. LAURENCE 777BRZ CRL Bronze 777 Butyl Rubber Sealant

MSRP:

Was:

$83.64

Now:

$41.82

Add to Cart

The item has been added

CRL Black 777 Butyl Rubber Sealant

MSRP:

Was:

$79.50

Now:

$39.75

Add to Cart

The item has been added

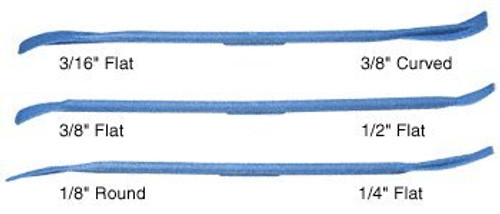

CRL Sealant Spatulas by CR Laurence

MSRP:

Was:

$119.90

Now:

$59.95

Add to Cart

The item has been added

CR LAURENCE CRL7711 CRL Windshield Sealant

MSRP:

Was:

$86.26

Now:

$43.13

Add to Cart

The item has been added

CR Laurence CRL7708 CRL Windshield and Body Sealant

MSRP:

Was:

$84.90

Now:

$42.45

Add to Cart

The item has been added

CRL Clear Silicone Sealant in 3 Fl. Oz. Squeeze Tubes by CR Laurence

MSRP:

Was:

$82.84

Now:

$41.42

Add to Cart

The item has been added

CR LAURENCE HA0208W CRL Milgard Door Keeper by CR Laurence

MSRP:

Was:

$101.90

Now:

$50.95

Add to Cart

The item has been added

CRL Sunroof Butyl Sealant Tape

MSRP:

Was:

$127.92

Now:

$63.96

Add to Cart

The item has been added

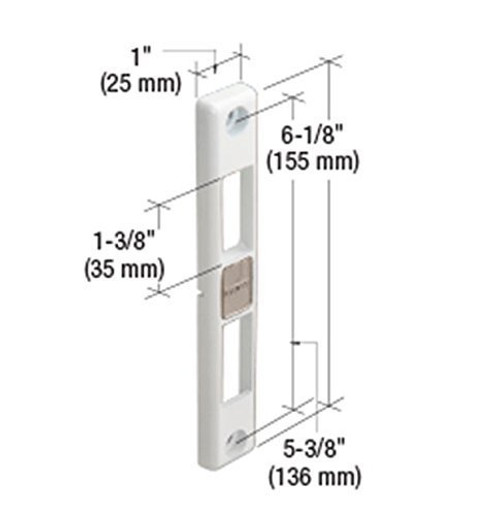

CR LAURENCE S4336 CRL White Window Lock

MSRP:

Was:

$83.30

Now:

$41.65

!